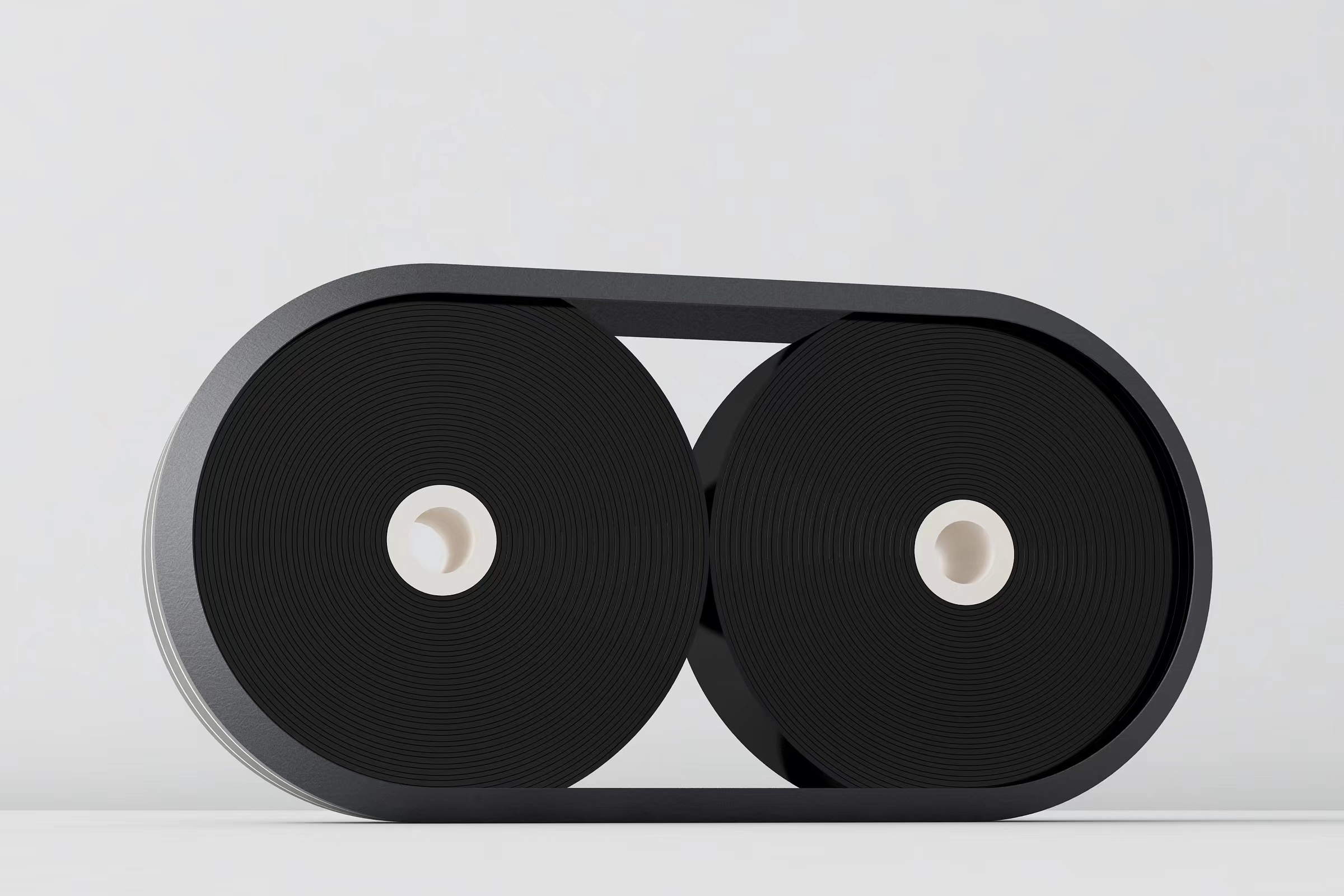

CC56 CONVEYOR BELT protection

- Categories:CC56 CONVEYOR BELT

- Author:

- Origin:

- Time of issue:2022-04-14

- Views:0

(Summary description)The task of the feeding device is to ensure that the transported material is loaded on the CC56 CONVEYOR BELT, and the service life of the conveyor belt is largely related to the structure of the feeding device.

CC56 CONVEYOR BELT protection

(Summary description)The task of the feeding device is to ensure that the transported material is loaded on the CC56 CONVEYOR BELT, and the service life of the conveyor belt is largely related to the structure of the feeding device.

- Categories:CC56 CONVEYOR BELT

- Author:

- Origin:

- Time of issue:2022-04-14

- Views:0

1. Optimization of the structure of the feeding device

The task of the feeding device is to ensure that the transported material is loaded on the CC56 CONVEYOR BELT, and the service life of the conveyor belt is largely related to the structure of the feeding device. The design of the feeding device structure has the following requirements: when the material is loaded into the conveyor, the speed and direction of the material should be close to the running speed and direction of the conveyor belt; the material should be installed on the center of the conveyor belt, and the material should not be spilled on the conveyor. When transporting bulk materials, try to avoid the impact of the material on the conveyor belt and reduce the feeding height as much as possible; the feeding amount is adjustable to maintain a good passing ability; The material flow is continuous.

2. Reduce the impact of the receiving process on the conveyor belt

According to the survey, 70% of the damage of the CC56 CONVEYOR BELT is caused by breakdown damage and scraper, so reducing the impact of the material receiving process on the belt will greatly increase the life of the conveyor belt. The methods of reducing the impact of materials on the conveyor belt are: optimizing the feeding method of the material; improving the impact resistance of the conveyor belt and the idler; improving the surface performance of the idler, reducing the quality of the idler under the condition of strength; The distance between the rollers can reduce the displacement quality of the roller group; the buffer device with hanging spring is adopted; the elastic connection is added between the rollers; the multi-idler roller group is adopted; the height of each roller group is different Completely parallel arrangement; secondary buffering is used to reduce shock when necessary.

3. Adopt electromechanical protection device

According to the needs of use conditions, select a reasonable electromechanical protection device to ensure the normal operation of the CC56 CONVEYOR BELT, and can improve the life of the conveyor belt. The conveyor should be equipped with anti-deviation device, belt speed detection protection device, longitudinal tear protection device of conveyor belt, chute blockage detection device, emergency stop device, metal debris detection and removal device, and belt break protection device according to the equipment conditions. Wait.

Scan the QR code to read on your phone

Add: Tingtou Industrial Zone, Sanhe, Tiantai, Zhejiang

Tel:

+86-576-83087811

Fax: +86-576-83087822

E-mail:

info@sjbelt.com

SEARCH

Whatever your goal, we'll get you there!